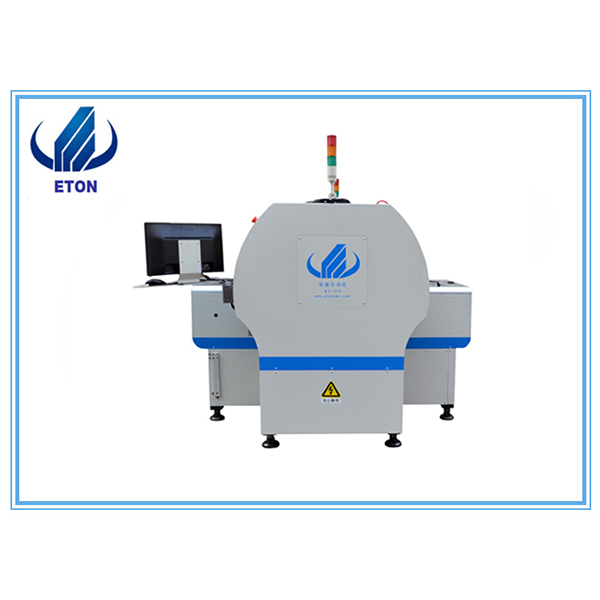

Quality Inspection for Automatic Smd Led Placement Machine - Middle High Precision Visual Position Placement Machine E5 Chip Mounting Machine for LED Manufacturing Machine Line – Eton

Quality Inspection for Automatic Smd Led Placement Machine - Middle High Precision Visual Position Placement Machine E5 Chip Mounting Machine for LED Manufacturing Machine Line – Eton Detail:

1 . Features :

1.Dual vision system identify and calibrate the different components at one time, improves the accuracy of placement from 0402 to BGA;

2. Automatic electric feeders, reduce the feeding deviation;

3. General conveyor is supported, so a SMT production line can be setup, which is more time-saving and labor-saving

4. Eight placement heads can pick up and calibrate components at one time.

5. The device supports remote system upgrade, ETON provides a life long system upgrade service for free to you;

6.Big display contributes to easier and convenient operation.

2. FRQ

We own excellent sales team,top-tech R&D team and professional management group

1.Leaders of highspeed pick and place machine industry

2. Machines has sold to all over the world

3. Products have a good reputation in the market

4. Perfect after sales system

3 . Technical Parameter :

| Model | SMT chip mounter HT-E5 | |

| Machine Style | Single gantry with 8 heads | |

| Alignment | Stage Vision | |

| Placement Rate | Vision:35,000CPH(Optimum) | |

| Feeder Capacity | Tape feeder:8mm,12mm,16mm,24mm is avaible | |

| Vibration feeder is avaible | ||

| Component Range | Smallest Size | 0402 |

| Largest Size | 30mm (Pitch 0.2mm) | |

| Max Height | 3mm | |

| Rotation | ±360° | |

| Placement Accuracy | ± 0.02mm(repeat placement accuracy | |

| X-Y Repeatability | ±0.02mm | |

| Board Dimension(mm) | Maximum | 500 x 350mm |

| Minimum | 50 x 50mm(Option) | |

| Main Control | GUI | |

| Electricity Supply | 220V | |

| Power | 4KW | |

| Weight | 1370KG | |

4 . Product Image :

5 .Company Information

ETON has launched its new Middle-speed SMT Pick and Place Machine, Equipped with a newly developed parallel 8 nozzle head, the ETON SMT Pick and Place Machine is capable of mounting a wide variety of parts and improving the mounting speed by up to 20~30%. The ETON Pick and Place Machine is robotic assembly machine for mounting electronic components on a " PCB" in the printed board mounting process. In addition to increasing the number of components mounted per cycle, ETON Pick and Place Machine also includes a new mechanism to improve the mounting speed by automatically changing the recognition sensor height.

6 .Packaging & Shipping

1)Standard wooden case package with vacuum package

2)Strong wood package for heavy and large equipment

7 .Our Services

Excellent Service .

Upgrade the software will be free for whole lifetime of machine .

Visit customer regularly and gather information .

Pre-Sales Service

* Inquiry and consulting support.

* Sample machine testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Professional is our truth. Let's light up your business.

Product detail pictures:

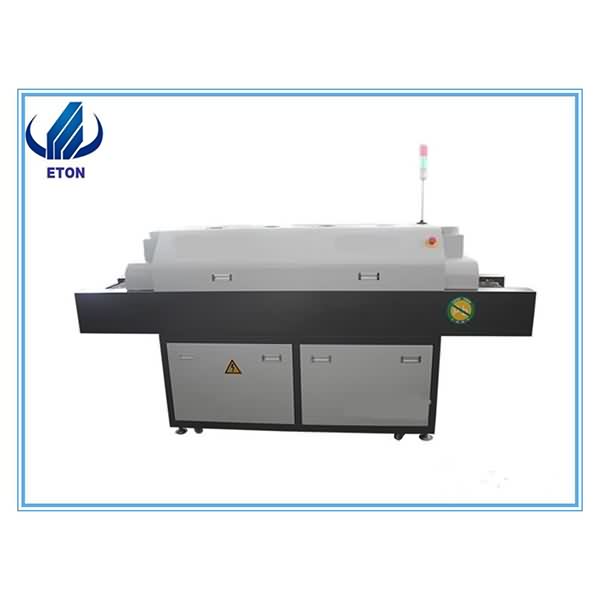

Related Product Guide:

AMD reveals full Ryzen Threadripper launch line-up • Eurogamer.net | Smt Chip Shooter

Spine-like lithium-ion battery can be flexed and twisted | Smt Chip Shooter

We thinks what customers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better good quality, lower processing costs, prices are extra reasonable, won the new and old buyers the support and affirmation for Quality Inspection for Automatic Smd Led Placement Machine - Middle High Precision Visual Position Placement Machine E5 Chip Mounting Machine for LED Manufacturing Machine Line – Eton , The product will supply to all over the world, such as: Bulgaria , San Francisco , Slovenia , With the effort to keep pace with world's trend, we'll always endeavor to meet customers' demands. If you want develop any other new items, we can customize them to suit your needs. If you feel interest in any of our products and solutions or want develop new merchandise, you should feel free to contact us. We are looking forward to forming successful business relationship with customers all over the world.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.