Quality Inspection for Automatic Smd Led Placement Machine - Double Model 16 Head Automatic PCB Chip Mounting Led Production Machine SMT Pick And Place Machine E8T-1200 – Eton

Quality Inspection for Automatic Smd Led Placement Machine - Double Model 16 Head Automatic PCB Chip Mounting Led Production Machine SMT Pick And Place Machine E8T-1200 – Eton Detail:

1 .Features :

♦ Auto-optimization feature after coordinates generated

♦ Electronic feeder feeding system .

♦ Flight identification ,Vision camera ,Mark correction ,more precision

♦ It can produce all kinds of LED light ,power driver ,electric board ,display etc .

♦ IPC9850 Capacity : 70000 CPH

Apply to the SMT machine , PCB ,LED hard light board and LED soft lamp strip etc .

Apply to electric board ,tube ,driver ,bulb ,strip ,lamp ,panel ,ceiling light ,down light ,screen ,street light ,flood light ,etc .

Apply to LED chip ,capacitors ,resistors ,IC ,shaped components etc . (intelligent ,use widely )

16 nozzles altogether ,34 feeders ,partA or partB can be mounted separatly . Easy to operate .

Patent Number : ZL 2011 2 0237740.9/ZL 2011 2 0334606.0

ZL 2012 2 0178869.1/ZL 2012 2 0415505.0

ZL 2012 2 0415044.7/ZL 2012 2 0415356.8/ZL 2012 2 0415061.0

2 .Technical Parameter :

| Dimension | 2950mm(L)/2150mm(W)/1500mm(H) |

| PCB Length Width | Max. :350mm*1200mm Min. :50mm*50mm(W*L) |

| PCB Thickness | 0.5~5mm |

| Mounting Precision | ±0.02mm |

| Components | LED chip,IC,capacitors,resistors,shaped components etc. |

| Power Comsumption | 8KW/220AC 50HZ |

| Air Force | 0.5mpa |

| System | Windows 7 |

| Mounting Speed | 70000CPH |

3 .Our Advantage :

Date Analysis Compared with other Manufacturers

| Manufacturers/Parameter | Speed | Head | Precision | Patent | service |

| Other company F130 | 15000CHP | 4PCS | 0.03mm | __ __ | NO |

| Other company 5M168 | 18000CHP | 6PCS | 0.03mm | __ __ | NO |

| Our Eton HT-XF | 150000~170000CPH | 34PCS | 0.02mm | Technology Patents | service office |

| Our Eton HT-T7 | 100000~130000CPH | 60PCS | 0.02mm | Technology Patents | service office |

| Our Eton HT-E8T | 80000CPH | 16PCS | 0.02mm | Technology Patents | service office |

| Data Comparision | 4 to 8 times higher than others | 4 to 8 times higher than others | higher precision | Global First | Support promptly |

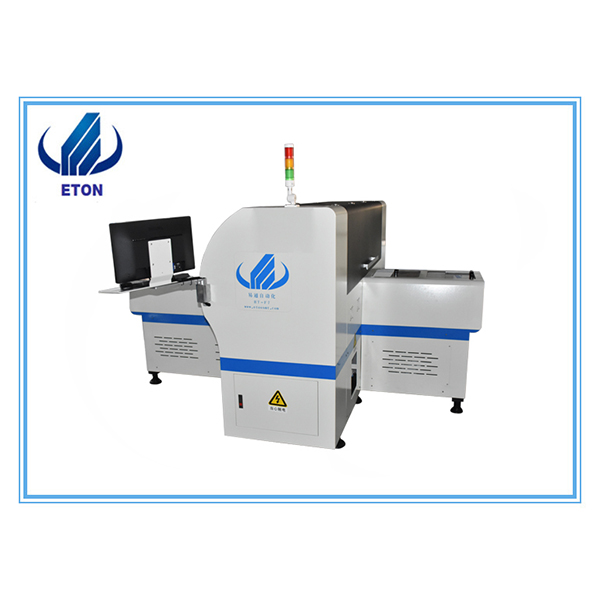

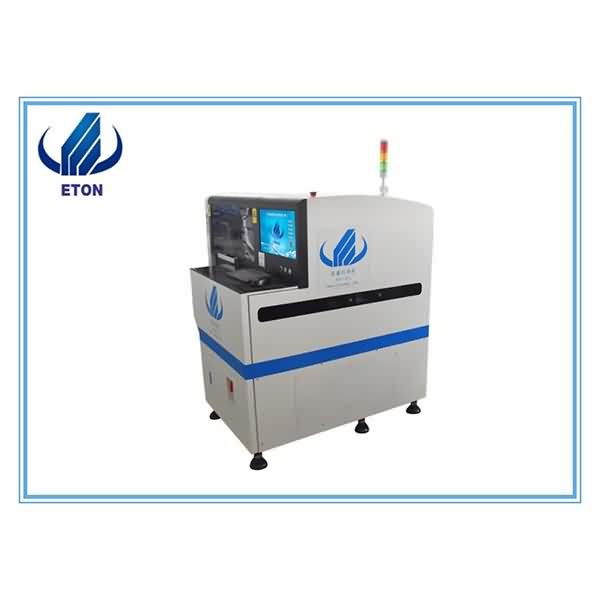

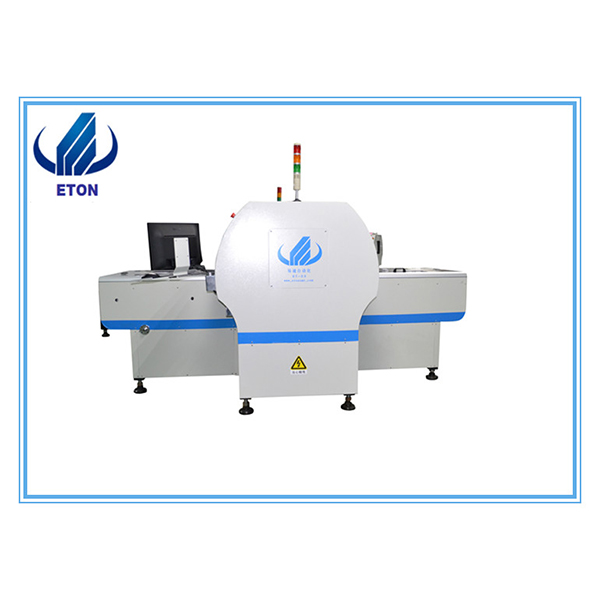

4 .Product Image :

5 .Company Information

Company Profile :

The Global Largest Production Capacity Supplier of LED Production Line

Professional Efficient Technology Development Innovation

Company Five Level Management Policy : sincere business ,focus on R&D ,manufacture by heart ,considerate service , customer trust .

Eton Purpose : To create value for customers , creating benefits for society .

Eton Mission : Professional ,Excellent technology ,Share the results .

6 .Packaging & Shipping

Package : Standard export package (Package as per customer 's requirement )

Shipping : Shenzhen port within 15 days after payment

7 .Our Services

Excellent After-sale Service .

Upgrade the software will be free for whole lifetime of machine .

Visit customer regularly and gather information .

8 .Patents Certifications :

FAQ

1.What's LED pick and place machine?

As we know,LED is used popularly all over the world,so the demands and requirements of LED production line are increasing rapidly.And the LED pick and place machine the most important part in producing LED light. Patching the LED is the key process.

2.What are the normal requirements about LED pick and place machine?

Because the patch is the key process in producing LED,there are many normal requirements:Stable,High-speed,High-precision, Intelligent,Durable etc..

3.What are the main LED products do our machines for?

There are different machines in our company,and different machines apply to different LED lights. The main products we can apply:bulb,tube,strip,lamp,panel.downlight,streetlight,ceiling light.wall washer light and so on.

4.Do our machines only for LED lights?

No,our machines apply to not only LED light but also other products.

5.What components do our machines apply to?

Our machines can patch LED 3014/3020/3528/2835/5050/5630/5730 etc.,capacitors,resistors,IC,shaped components and so on .

Professional is our truth. Let's light up your business.

Product detail pictures:

Related Product Guide:

Switch Has Outsold The Original And Slim PlayStation 4 In Japan | Smd Led Placement Machine

Intel rips up microcode security fix license that banned benchmarking • The Register | Pcb Separator

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Quality Inspection for Automatic Smd Led Placement Machine - Double Model 16 Head Automatic PCB Chip Mounting Led Production Machine SMT Pick And Place Machine E8T-1200 – Eton , The product will supply to all over the world, such as: Southampton , Brisbane , Eindhoven , With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our products in China!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.