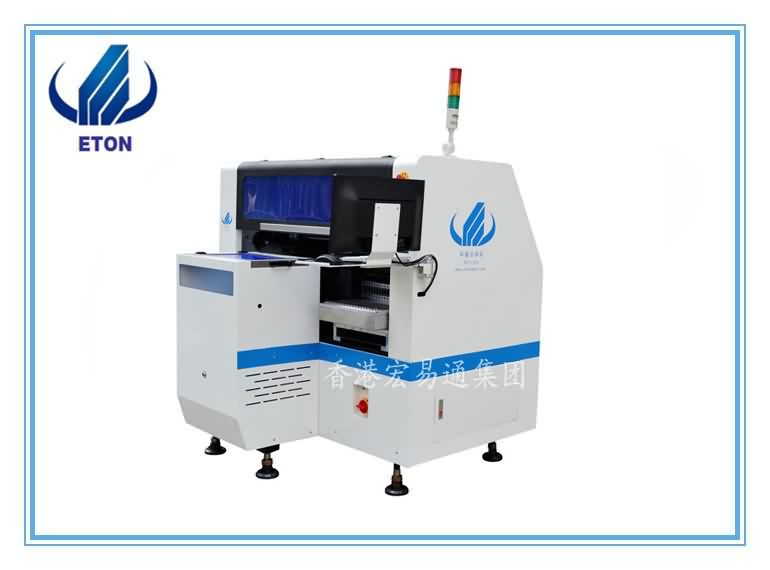

Original Factory Desktop Led Making Machine - Middle Speed Small LED Pick And Place Machine HT-E6T-1200,For Tube,Bulb,Strip,Panel,Downlight,Ceiling Light,Streetlight – Eton

Original Factory Desktop Led Making Machine - Middle Speed Small LED Pick And Place Machine HT-E6T-1200,For Tube,Bulb,Strip,Panel,Downlight,Ceiling Light,Streetlight – Eton Detail:

1.Features

1.pick and place machine HT-E6T-600 eight-headed Pick up.

2.Two sets of high-speed flight cameras,1set of precision camera and set of Mark identification.

3.Computer Control.

4.Automatic Identification Of Mark Point.

5.Fuji servo motor in Japan.

6.Japanese KURODA ball screw.

7.Components Available: 0402,resistor,capacitor,IC,Shaped components etc.

8.Automatic transmission of PCB board.

9.Full English interface.

10.Professional remote video technical support.

2. FRQ :

1.Powerful software adopts numbers and images to display the program coordinate, easy and more convenient.

2.Software adopts data system, and store different types of PCB for convenient adjustment, just need to program one time for new products to use forever.

3.Platform: Y axis, X axis can be moved manually, speed adjustable, can achieve arbitrary point manual arrived, convenient programming.

4.LED Pick & Place Machine use imported vacuum detection system, it can check the suction accurately to prevent material leakage and throwing effectively.

5.Internal negative pressure system: low noise, long service life and vacuum pressure constant.

6.Standard setting:1 PC,6 mounting heads,18 nozzles.

7.Optional:8mm,12mm,16mm,and 24mm automatic feeder, different nozzles, industrial pump, air compressor .

3.Technical Parameter:

| Dimension | 1950mm(L)/2400mm(W)/1550mm(H) |

| PCB Length Width | Max.:350mm*600mm Min.:50mm*50mm(W*L) |

| PCB Thickness | 0.5~5mm |

| Mounting Precision | ±0.02mm |

| Components | LED chip,IC,capacitors,resistors,shaped components etc. |

| Power Comsumption | 4KW/220AC 50HZ |

| Air Force | 0.5mpa |

| System | Windows 7 |

| Mounting Speed | 35000CPH |

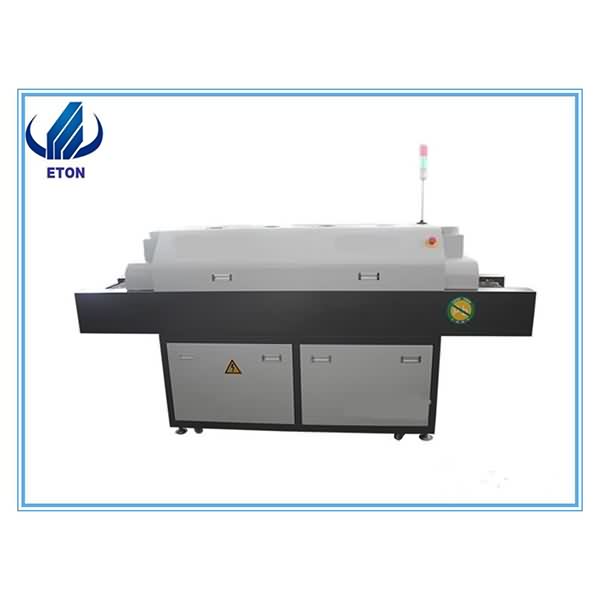

4.Product Image:

Professional is our truth. Let's light up your business.

Product detail pictures:

Related Product Guide:

Cadence and Lumerical Announce Photonics Summit | Smd Led Placement Machine

Polytetrafluoroethylene (PTFE) Coatings Market 2023 by Emerging Key Players, Top Countries, Types, Applications, and Forecast Details | Smt Chip Shooter

To create far more benefit for customers is our company philosophy; customer growing is our working chase for Original Factory Desktop Led Making Machine - Middle Speed Small LED Pick And Place Machine HT-E6T-1200,For Tube,Bulb,Strip,Panel,Downlight,Ceiling Light,Streetlight – Eton , The product will supply to all over the world, such as: Miami , Croatia , Tunisia , So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary items we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.