1. Classified by patch

This kind of classification method is not very commonly used in actual production. It is only used in theoretical analysis and classified according to patch method. The placement machine can be divided into four types: sequential, online, synchronous and simultaneous/online. See the table for application scale.

2. Classified by patch speed (patch rate)

According to the patch speed classification, the placement machine can be divided into low speed, medium speed, high speed and massive patch system (slice rate is more than 20,000 / h).

(1) Low-speed placement machine The placement rate of the low-speed placement machine is less than 3000/h. The placement cycle time is usually less than 1 s/point, which is usually applied to product trial production, new product development, small batch production and special SMC/SMD placement.

(2) Medium speed placement machine The medium-speed placement machine usually has a placement rate of 3000-8000/h, and the patch cycle time is usually 1-0.5 s/point. It is suitable for SMC/SMD with a wide scale, rich accessories, perfect functions, high patch accuracy and certain production efficiency. In addition, the performance price of the equipment is relatively moderate, and it is the preferred equipment for small and medium batch production.

(3) High-speed placement machine The high-speed placement machine has a placement rate of 8000/h or more, and the patch cycle time is less than 0.4s/point. It has high production efficiency and is suitable for mass production. It is especially suitable for the production of chip capacitors, chip resistors, small SMD and a small amount of special SMD.

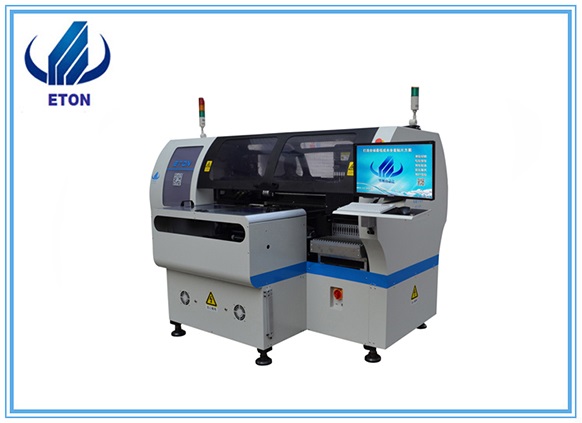

AUTOMATIC PICK AND PLACE MACHINE PCB MOUNTING MACHINE SMT PRODUCTION LINE PICK AND PLACE MACHINE FOR LED BULB

Post time: Aug-28-2020