Manufacturing Companies for Manul Selective Wave Soldering Machine - Digital Display With Programmable Reflow Welding Machine Programmable Reflow Oven Smt 5 Zones Reflow Oven – Eton

Manufacturing Companies for Manul Selective Wave Soldering Machine - Digital Display With Programmable Reflow Welding Machine Programmable Reflow Oven Smt 5 Zones Reflow Oven – Eton Detail:

1.Features:

Forced cooling system with efficient cooling speed suits all different kinds of lead-free soldering paste.

PLC and PID closed loop control to achieve high precision temperature control and repeatable profiles.

The rail is dealt with hardened process to make it more stability.

The rail width can be adjusted by manual.(option:automatically by SPG gear motor).

Chain Rails will be lubricated by central oil reservior device ,controlled by computer.

Strong software system can save all settings and can print all the data and profiles through PC.

With flux collecting system to keep inside zones clean and ensures more environmental emission.

Control System: PC + Siemens PLC control system,accurate temperature control and more stable,ensures temperature stability rate to be more than 99.99%.

Hot air system: first-class heating module, the best temperature zone interval design makes optimum temperature uniformity and repeat.The effective utilization and thermal compensation efficiency,it needs less than 20 minutes from temperature control accuracy ± 1 ℃ ambient temperature to a temperature stabilization .

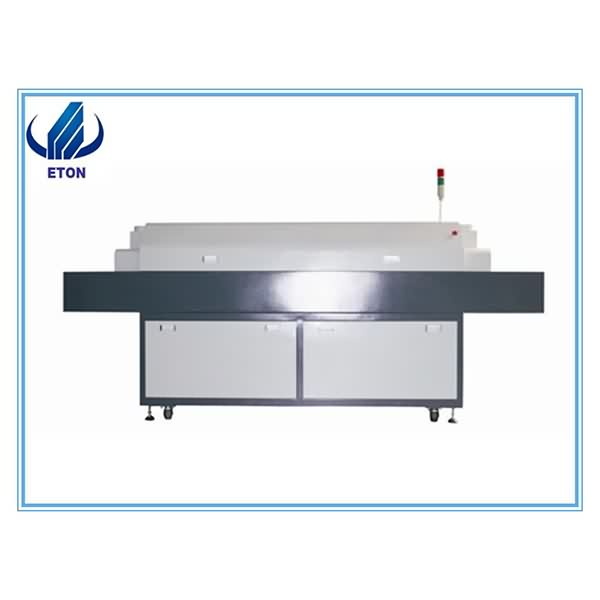

2.Machine image

3.FRQ

Are you a trade company or a manufacturer?

OEM & ODM service are available.

What is your delivery date?

The delivery date is about 35 days after receipt of payment.

What is your payment terms?

30% deposit in advance and 70% balance before shipment.

Our Main equipment:

Main Products:SMT LED Pick and Place Machine,SMT LED Reflow Oven,SMT LED Stencil Printer,SMT Production Line,LED Assembly Line,SMT LED Machine.

Our Successful Experience:

1.We have been helping customers to build a lot of new factories and enlarge the production line all over the world.

2.Leading manufacturer of the highspeed pick and place machine

3.Own global first technology patents.

4.Training more than 5000 experts and technician for customers.

5.The most reliable and popular Chinese partner for you.

Product detail pictures:

Related Product Guide:

Plywood units asked to follow PCB’s green plan | Smt Chip Shooter

Live From the U.S. Open: Fox Sports and Partners Make an Innovative Difference | Pcb Separator

We pursue the administration tenet of "Quality is remarkable, Services is supreme, Status is first", and will sincerely create and share success with all customers for Manufacturing Companies for Manul Selective Wave Soldering Machine - Digital Display With Programmable Reflow Welding Machine Programmable Reflow Oven Smt 5 Zones Reflow Oven – Eton , The product will supply to all over the world, such as: Belize , Hyderabad , Slovenia , What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.