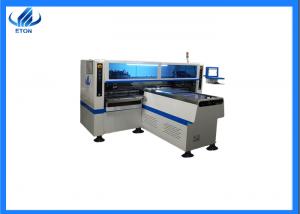

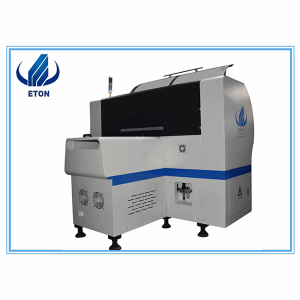

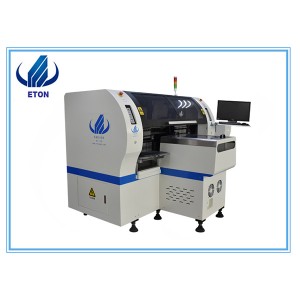

Magnetic levitation high speed mounter for unlimited length flexible strip(no wire),capacity reach 200000CPH

Product details

Price: $ 95,000 /unit

Customization: According to customer needs.

Components: LED3014/3020/3528/5050 and resistor,capacitors,bridge rectifiers,etc.

Application:5m,50m or any length of flexible strip and roll to roll;RGB

technical parameter:

| Model number |

HT-T9 |

| Dimension |

2450*2100*1550mm |

| PCB size |

250mm*any length |

| PCB thickness |

0.5~1.5mm |

| PCB clamping |

adjustable pressure pneumatic |

| mounting mode |

group to take and group to mount |

| system |

windows 7 |

| display |

touch screen monitor |

| input device |

keyboard,mouse |

| NO.of camera |

5 sets of imported camera |

| mounting precision |

±0.02mm |

| mounting height |

<13mm |

| mounting speed |

200000CPH |

| components space |

0.2mm |

| NO.of feedings station |

64pcs |

| NO.of nozzles |

64pcs |

| power |

380AC 50HZ |

| power consumption |

6KW |

| operating environment |

23℃±3℃ |

| conveyor transmission |

any length |

| transmission speed |

>500mm/sec |

| transmission direction |

single(left→right,right→left) |

| transmission mode |

online drive |

| position mode |

optical |

| Air Force |

0.5mpa |

| electrical control |

independent research and development by ETON |

| motion control card module 1set |

independent research and development by ETON |

| X.Y axis drive way |

high-end magnetic linear motor+servo motor |

| feeding way |

electric feeder with double motor |

Product parts:

- Saline shaft from korea

- Mark camera from HK vision

- Grating scale from Renishaw,UK

- Guideway from IKO Japan

- Pneumatic components from SMC Japan

- Sensor from Beckhoff Germany

- Drag chain from IGUS Germany

Product feature:

- Producing with 2~4 types of materials with high capacity at same time.

- Single plate material can be mounted, and the same plate material is always mounted on the same lamp.

- Dual-arm four modules with 16 nozzles for each mounting part, and part A/B/C/D can be mounted separately or synchronously.

- Calibration automatically.

- Exclusive patent technology:group to pick and group to mount.

- IPC9850 capacity: 100000~150000CPH

Company profile

Shenzhen ETON automation equipment co., LTD., founded in 2011, is a company dedicated to SMT high-speed placement machine research and development, production, sales and after-sale technical services integrated national high and new technology, the double soft enterprise. The company always adhere to the "create national brands, to build international enterprise in China" goals, is committed to providing customers with "professional, efficient, low consumption" fully automatic SMT placement machine.ETON mission: professional, excellent technology, sharing the results.

ETON’ s purpose: to create value for customers,creating benefits for society.

ETON vision: determined to become the world’s most competitive manufacturer and service provider of pick and place machine and high-end electronic testing equipment.

Quality principle: quality first, client-oriented, continuous improvement!

Management policy: sincere business,focus on R&D,manufacturing intentions, considerate service,customer trust.

| Business type |

Manufacturer,distributor/wholesales |

| Year established |

2011 |

| ownership | |

| Country/region |

Guangdong, China |

| Total employees |

101-200 people |

| Main products |

Pick and place machine, SMT LED machine, LED light production machine, LED light assembly machine. |

| Total annual revenue |

US$1million - US$2.5million |

| Supply ability |

80 Units per Month |

| Product certification |

CE , CCC , SIRA |

| Main markets |

Domestic market 70.00%, Southeast Asia 8.00%, South Asia 7.00% |

Business terms:

| Accepted delivery terms | EXW, FOB, CIF, CFR |

| Accepted payment currency | USD,CNY |

| Accepted payment type | L/C, T/T |

| Nearest port | Shenzhen |

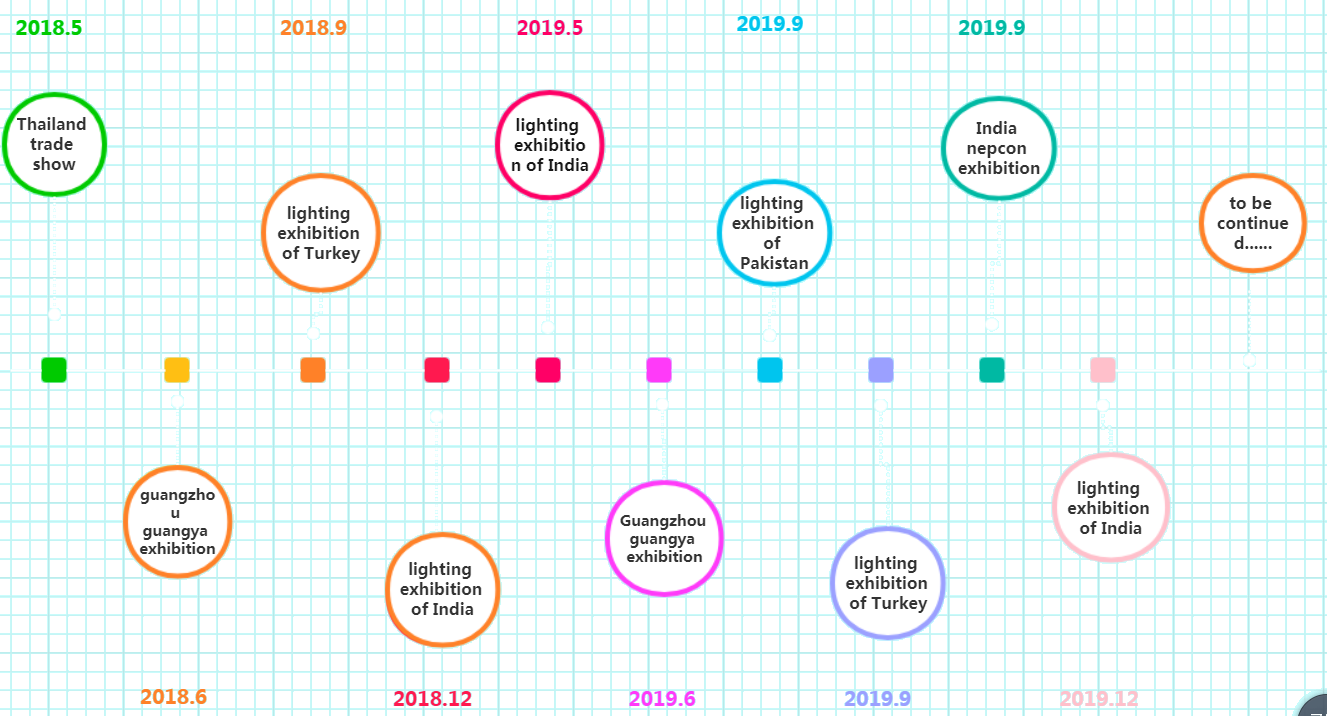

Trade show:

Our clients:

We occupy more than 80% of the domestic market in China, and our products have a good reputation.Our clients are long-term partners.At the same time, our products are exported to more than 20 countries, including Korea, India, Turkey, Pakistan, etc.

FAQ

1) Do you have oversea after sale service?

We have set up an overseas office in India.We can offer technical support abroad. If you have any technical problem, our engineers will support you promptly.

2)How is the training?

You can send your engineers to our workshop to study, or we can send our engineers to your workshop for guidance. We guarantee that the training will not be completed until your operators are fully trained.

3) It’s hard to use the machine?

No, not at all. Touch screen display, English operation interface. Generally training about five days can be skilled in the operation of the machine.

4) Does your machines have quality certificates?

We are high-tech enterprise with CE,SIRA,CCC .

5)How about the warranty?

We guarantee it for one year free of charge. Software updates are free for life.

Industry knowledge

SMT patch equipment production line

lSoldering press

A solder paste press is located at the front end of a SMT production line and is used to print solder paste or patch glue. It prints the solder paste or patch glue correctly to the pad or corresponding position of the PCB to prepare for the mounting of the components. presses for SMT are broadly divided into three types: manual, semi-automatic, and fully automatic.

a patch seat is at the back of the printing press in the SMT production line. The function is to remove the surface mount components from the packaging and install them accurately to the fixed position of the printed circuit board. SMT loading function and production capacity of the production line mainly depend on the function and speed of the loading machine.

lPlacement machine

A placement machine is the equipment with the highest technical content, the most complex and the most expensive in the SMT production line. Full automatic mount machine is a high speed, high precision, high automation and highly intelligent equipment which integrates precision machinery, electric, pneumatic, optical, computer, sensing technology and so on. SMT the production line, the configuration of the placement machine should be determined according to the type and output of the products produced.

Backflow welder is located at the back of the placement machine in the SMT production line. its function is to provide a heating environment to melt the solder paste pre-assigned to the pcb pad so that the surface mount components are reliably combined with the PCB pad through the solder paste alloy.

lBackflow Welding Machine

Backflow welding is a kind of electronic product assembly technology suitable for automatic production, which has become the mainstream of SMT circuit board assembly technology.

lTesting equipment

function of the testing equipment is to test the assembly quality and welding quality of the pasted PCB. The equipment used is magnifying glass, microscope, automatic optical detector (AOI), on-line tester (ICT), X-RAY detection system, functional tester, etc. According to the need of testing, its installation position is behind the corresponding station in the production line.

l Repairable equipment

A repairable equipment is used to rework PCB that detect malfunctions. The tools used are soldering iron, rework workstation, etc.

l Cleaning equipment

Cleaning equipment is used to remove PCB attached to the material that affects electrical properties or harmful welding residues such as flux. If the use of clean-free solder, generally can not be cleaned. The equipment used for cleaning is ultrasonic cleaning machine and special cleaning liquid, its installation position is not fixed, can be online or not online.

contact

Name:Brynn

Email :Brynn@eton-mounter.com

WeChat:13802252825

Telephone:138 0225 2825