HT-E8D Main parameters

HT-E8D Main parameters

| Dimension | L*W*H 310*2250*1650MM |

| Weight | 2000kg |

| Mounting Heads | 16 Heads |

| No. of Feeder Stations | 80 Stations |

| Components | LED, capacitors, resistors, shaped components, IC, etc. |

| Mounting Speed | 80000 CPH |

| Components Size | Max:18MM Min:0402 |

| Power | 380V 50Hz |

| X.Y Axis Driving | High-end magnetic Linear motor + servo motor |

HT-E8D Application

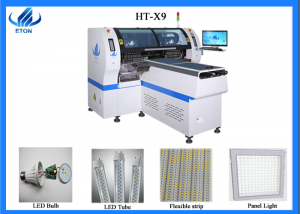

HT-E8D can meet 0402 components, Max mounting height can be 36MM. It’s suitable for various types of drives, power supplies, circuit boards, lenses, linear bulbs, home appliance control panels, LEDs etc.

HT-E8D is also a dual module dual system double rails machine so you use this machine to produce two products at one time.

Company’s Window

Eton information

Shenzhen Eton Automation Equipment Co., Ltd established in 2009. Which is national high-tech enterprise. We concentrate on building national brand and provides customers with professional, efficient, low consumption and specializes in R$D, production, sales and service of SMT automatic high-speed placement machine.

Eton owns nearly 300 employees, 80 of them are production work man for the pick-and-place machine, and other 40 engineers are responsible for developing the domestic pick-and-place machine.

Eton services:

1) Professional sales manager of LED SMT machine, provide professional suggestion and service to you !

2) Sound company organization and working system, guarantee you a fast delivery!

3) Design and provide the whole SMT processing lines for you based on your budget , workshop covering area with best prices!

Choose Eton, light up your business!

1. General

(1) Why choose us?

Answer: Eton owns the capacity of self-research and manufacturing, and obtains a series of invention and utility patents under the honor of national high-tech enterprise. Also, with more than fifty after-sales engineers, each of whom can solve your any requirement timely.

(2) MOQ?

Answer: There is no minimum quantity, so you can just order a few or even just one machine, the price depends on quantity.

(3) What are the shipping methods, and how long?

Answer: By sea: 20-40days.

By train: 20-30 days (including tax and custom clearance).

Our suggestion is ocean shipping that owns a high cost performance.

(4) How is the training?

Answer: your engineers can visit our company to have training or we dispatch experts to your factory, who will train your engineers how to use these machines.

2. Special

(1) If I use your pick and place machine, what kind of infrastructures I need to prepare?

Answer: Because pick and place machine is high accurate equipment, it has a high requirement for the factory environment. First, most suitable temperature is 22-32 degrees. Second, to meet the basic need of production, air compressor should be 7.5P or more. Third, try best to keep a non-dusty workshop. Fourth, in some area the power supply not stable enough, so one UPS is needed.

(2) What are the basic safety operations?

Answer: First, when everyday first start the machine, keep the speed on 20% 10 minutes for machine warmly. Second, Don’t directly open the cover when machine is doing production! If you need to open it, please press stop button first. Third, if you want to shut down the machine, please shut down the computer first, then turn off the rotary switch.

(3) How do I maintain this machine?

Answer: It's easy, at fixed period push few lube oil into the rail, and use non-dusty cloth wipe the raster ruler.