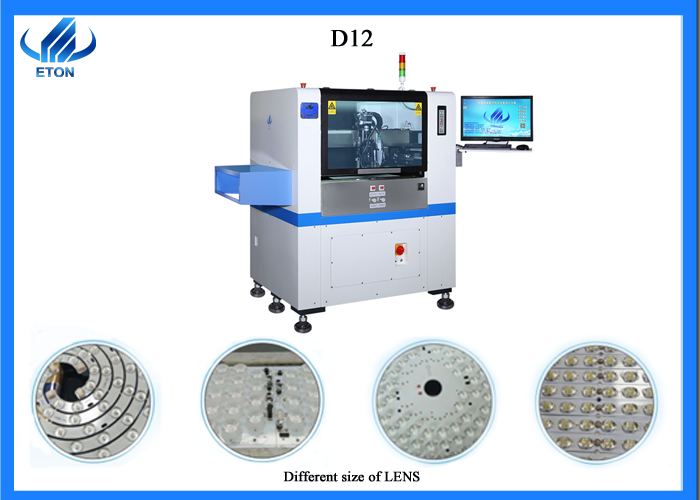

HT-D12 Parameters

Parameters

| Dimension | L*W*H 1800*1050*1550MM |

| Weight | 950kg |

| Mounting Heads | 10 Heads |

| No. of Feeder Stations | 32 Stations |

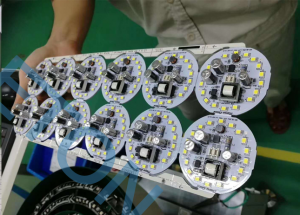

| Components | LED, capacitors, resistors, shaped components, IC, etc. |

| Mounting Speed | 40000 CPH |

| Components Size | Max:18MM Min:0402 |

| Power | 380V 50Hz |

| X.Y Axies Driving | High-end magnetic Linear motor + servo motor |

HD-12 Features

1l It adopts Chinese operation interface and is easy to understand.

2l Equipped with CCD positioning system, automatic visual positioning compensation, correcting the deviation of the board.

l3 Large-size carrier rails for PCBs of various sizes and sizes.

l4 Non-contact high-speed injection valve realizes continuous movement of the dispensing head to achieve high efficiency.

l 5High reliability and consistency of dispensing with the use of injection valves, as well as high productivity and material utilization

l6 Real-time monitoring of glue quantity, automatic prompt of low glue quantity

l 7Automatic constant temperature function of the valve body to ensure the fluidity of the gel.

l8 Valve switching time is controlled in milliseconds to achieve high consistency of dispensing size

l9 Online visual programming, using visual test mode, CAD map mode programming

l10 The program is automatically called to quickly start production and realize intelligent manufacturing.

l11 Dispensing for different products (such as disc, line, dot matrix)

l12 The X and Y axes are driven by high-performance linear servo motor to ensure high positioning accuracy under high-speed operation.

l13 With input and output signal interface, other devices can be connected to achieve production pipeline

l14 Configure industrial control system with high-capacity high-speed SSD, high-speed access to ensure system response speed

Successful Experience:

Eton’s customer in 35 countries around the world

1. We have been helping customers to build a lot of new factories around the world.

2. Training more than 500 experts and technician for customers.

3. Became the most reliable Chinese partner for you.

For SMT factory setup,we can do for you:

1. We provide fulL SMT solution for you

2. We provide core technology with our equipments

3. We provide the most professional tech service

4. We have wealthy experience on SMT factory setup

5. We can solve any question about SM