Good Quality Smt Selective Soldering Machine - Renewable Design for Low Cost Vertical Pick And Place Machine Led Smt Upright Pick Place Machine Pcb Component Vertical Pick And Place – Eton

Good Quality Smt Selective Soldering Machine - Renewable Design for Low Cost Vertical Pick And Place Machine Led Smt Upright Pick Place Machine Pcb Component Vertical Pick And Place – Eton Detail:

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Renewable Design for Low Cost Vertical Pick And Place Machine Led Smt Upright Pick Place Machine Pcb Component Vertical Pick And Place, We welcome new and previous shoppers from all walks of existence to contact us for long term organization relationships and acquiring mutual success!

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Led Smt Upright Pick Place Machine, Low Cost Vertical Pick And Place Machine, Pcb Component Vertical Pick And Place, Due to our good goods and services, we have received good reputation and credibility from local and international customers. If you need to have more information and are interested in any of our products, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

1.Features:

■ Windows operation interface, designed two kinds of control mode, computer control and emergency manual control,have the functions of security.

■ Adopting heating mode of the world top German technology, high heat transfer rate. The same temperature setting can reach more than 15% higher than the similar models of production capacity.The same capacity can be realized is lower than the similar machines of 15-20℃ further reduce the hot components on the PCB board and micro-damage.

■ Each temperature zone using forced circulation,independent PID control,upper and lower independent heating,the temperature of the furnace chamber accurate,uniform,large heat capacity.

| Model | REFLOW-X8 |

| Dimensions | 4800*1200*1450mm |

| Weight | 1400kg |

| Number district heating | 16 |

| Heating zone length | 3000mm |

| Number cooling zones | 2 |

| Exhaust volume requirements | 25cubic/minute |

| Control Systems | computer control |

| Power Requirements | 3Ø380v |

| Starting power | 45Kw |

| Normal power consumption | 7Kw |

| Heating time | 25minutes |

| Temperature control range | Room temperature-350℃ |

| Temperature control | Temperature range of the independent PID temperature control |

| Temperature control accuracy | ±1℃ |

| PCB distribution deviation | ±2℃ |

| PCB maximum width | 350mm |

| Parts height | 25mm |

| Transport direction | Left to right(right to left option) |

| Conveyor belt height | 900±20mm |

| Transport speed | 0-1800mm/min |

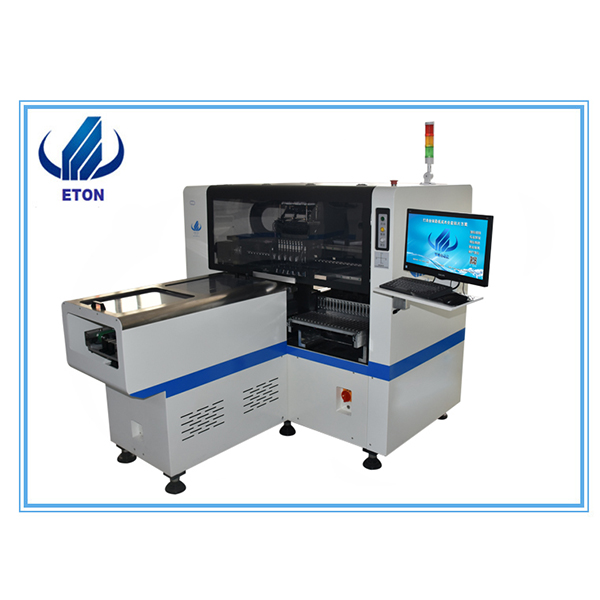

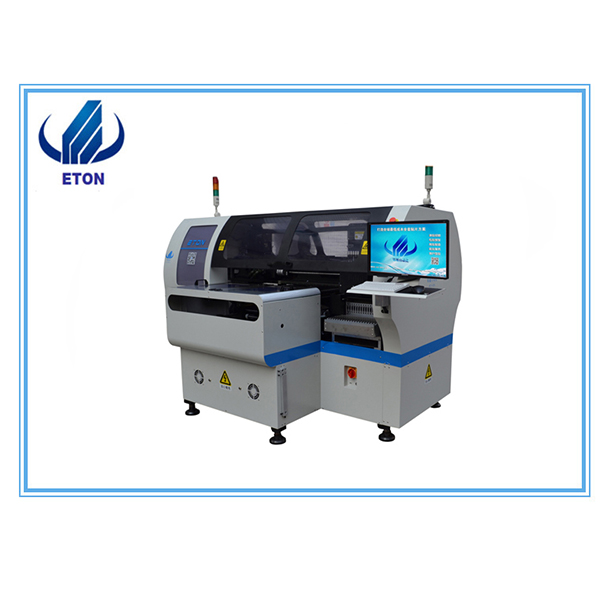

2.Machine image

3.Our Services

Technical support

1.From the date of purchase, two years of free repairs and maintenance;

2.Providing technical updates and technical services at any time;

3.The software system will be upgraded for a lifetime to ensure the latest and full features of the software version for free.

4.Provide technical training service according to customer’s requirements.

5.Can choose freely different feeding board ways and feeder bases.

Service Support

1.From the date of purchase, enjoy 24-hour service

2.make phone calls or on-site visits to customers non-scheduled , improve constantly according to the customer's requirements.

3.Guarantee to the expiration date, free to provide customers with Secure service

Product detail pictures:

Related Product Guide:

How Justdispose Recycling is Helping to Tackle the E-Waste Problem | Ic Card Chip Mounting Machine

AMD reveals full Ryzen Threadripper launch line-up • Eurogamer.net | Smt Chip Shooter

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Good Quality Smt Selective Soldering Machine - Renewable Design for Low Cost Vertical Pick And Place Machine Led Smt Upright Pick Place Machine Pcb Component Vertical Pick And Place – Eton , The product will supply to all over the world, such as: Nigeria , Pakistan , Lyon , With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.