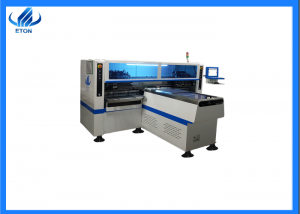

Dual-arm magnetic levitation LED high speed pick and place machine, capacity reach 200000CPH

Product details

Price: $80000/unit

Customization: According to customer needs.

- Producing with 2~4 types of materials with capacity at same time, available for 5m,50m or any length of flexible strip and roll to roll.

- Dual-arm four modules with 16 nozzles for each mounting part, and part A/B/C/D can be mounted separately or synchronously.

- Calibration automatically, high precision,available for RGB.

- Group to take and group to mount.

technical parameter

| Model number |

HT-F9 |

| Dimension |

2700*2120*1550mm |

| PCB size |

1200*330~80*330mm |

| PCB thickness |

0.5~5mm |

| PCB clamping |

adjustable pressure pneumatic |

| mounting mode |

group to take and group to mount |

| system |

windows 7 |

| display |

touch screen monitor |

| input device |

keyboard,mouse |

| NO.of camera |

5 sets of imported camera |

| mounting precision |

±0.03mm |

| mounting height |

<13mm |

| mounting speed |

200000CPH |

| components |

LED3014/3020/3528/5050 and resistors, capacitors, bridge rectifiers |

| components space |

0.2mm |

| NO.of feedings station |

68pcs |

| NO.of nozzles |

68pcs |

| power |

380AC 50HZ |

| power consumption |

6KW |

| operating environment |

23℃±3℃ |

| conveyor transmission |

MAX length:1200mm |

| transmission speed |

>500mm/sec |

| transmission direction |

single(left→right,right→left) |

| transmission mode |

online drive |

| position mode |

optical |

| air pressure |

>5.0kg/c㎡ |

| electrical control |

independent research and development by ETON |

| motion control card module 1set |

independent research and development by ETON |

| X.Y axis drive way |

high-end magnetic linear motor+servo motor |

| feeding way |

electric feeder with double motor |

Product parts

- Mark camera from HK vision

- Grating scale from Renishaw,UK

- Guideway from IKO, Japan

- Pneumatic components from SMC, Japan

- Drag chain from IGUS, Germany

- Transport guide from Hiwin, Taiwan

- Linear motor from Israel technology

- The host computer from EVOC

- Sensor from Beckhoff ,Germany

- The software is self-developed

Business terms:

| Accepted delivery terms | EXW, FOB, CIF, CFR |

| Accepted payment currency | USD,CNY |

| Accepted payment type | L/C, T/T |

| Nearest port | Shenzhen |

Product services

- We have a professional sales manager to provide you with professional advice and services.

- We will specify the production plan for you according to your budget.

- Provide latest information about technology and equipment.

- Software updates are free for life.

- We will visit the customer regularly to check and repair the machine.

supply ability

80 Unit/Units per Month

packing & shipping

We usually adopt waterproof packaging and will pack according to the customer's requirements. The nearest port is Shenzhen port. We usually arrange shipment within 30 days after payment.

1.Company profile

Shenzhen ETON automation equipment co., LTD., founded in 2011, is a company dedicated to SMT high-speed placement machine research and development, production, sales and after-sale technical services integrated national high and new technology, the double soft enterprise. The company always adhere to the "create national brands, to build international enterprise in China" goals, is committed to providing customers with "professional, efficient, low consumption" fully automatic SMT placement machine.ETON mission: professional, excellent technology, sharing the results.

ETON’ s purpose: to create value for customers,creating benefits for society.

ETON vision: determined to become the world’s most competitive manufacturer and service provider of pick and place machine and high-end electronic testing equipment.

Quality principle: quality first, client-oriented, continuous improvement!

Management policy: sincere business,focus on R&D,manufacturing intentions, considerate service,customer trust.

Trade shows

Our clients

The company has an absolute leading market share in the LED industry, we occupy more than 80% of the domestic market, and have a good reputation.Our products are exported to more than 20 countries such as Korea, India, Vietnam, Tunisia, Egypt, Turkey, etc.

FAQ

1) Do you have oversea after sale service?

We have set up an overseas office in India.We can offer technical support abroad. If you have any technical problem, our engineers will support you promptly.

2)How is the training?

You can send your engineers to our workshop to study, or we can send our engineers to your workshop for guidance. We guarantee that the training will not be completed until your operators are fully trained.

3) It’s hard to use the machine?

No, not at all. Touch screen display, English operation interface. Generally training about five days can be skilled in the operation of the machine.

4) Does your machines have quality certificates?

We are high-tech enterprise with CE,SIRA,CCC .

5)How about the warranty?

We guarantee it for one year free of charge. Software updates are free for life.

3.Knowledge of mounter industry

SMT mount cycle

mount cycle is the most basic parameter for marking mount speed. it refers to the time used when picking up components, after detection, sticking to the PCB and then returning the pick up component position. For each trip, complete a mount operation, that is, a mount cycle. The mounting period of Chip components is less than 0.2 s. At present, the maximum mounting period is 0.06-0.03 s;- and the mounting period of machine mounting QFP is 1~2.

Selection of Surface Mounting Components

selection and design of surface mounted components is a key part of the overall design of the product. the designer determines the electrical properties and functions of the components in the system structure and detailed circuit design stage. the packaging form and structure of surface assembled components should be determined in the SMT design stage according to the specific conditions of the equipment and process and the overall design requirements. solder joints installed on the surface are both mechanical and electrical connection points, and reasonable selection has a decisive effect on improving PCB design density, productivity, testability and reliability.

There is no difference in function between surface mounted components and plug-in components, the difference lies in the packaging of components. Choose the appropriate package, the main advantages are :1). effectively saving PCB area ;2). provide better electrical properties ;3). protect the interior of the components from environmental effects such as moisture ;4). provide good communication links ;5). help dissipate heat and facilitate transmission and testing.

contact

Name:Brynn

Email :Brynn@eton-mounter.com

WeChat:13802252825

Telephone:138 0225 2825