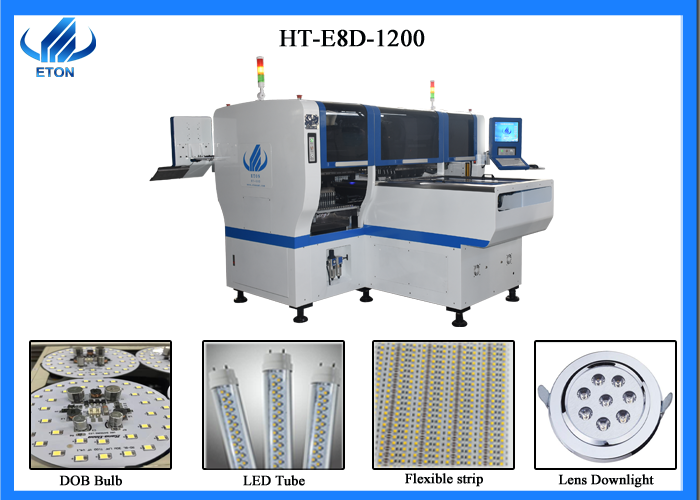

double-module magnetic linear motor multifunctional pick and place machine

product details

Price: $ 80000/unit

Customization: According to customer needs.

HT-E8D machine is Dual system,dual module multifunctional mounter with high capacity of 80000CPH. It can mount capacitors,resistors,LED3014/3020/3528/5050,IC and shaped components. It applies to power driver,electric board,lens,linear bulb,household appliance and etc.

Application example:

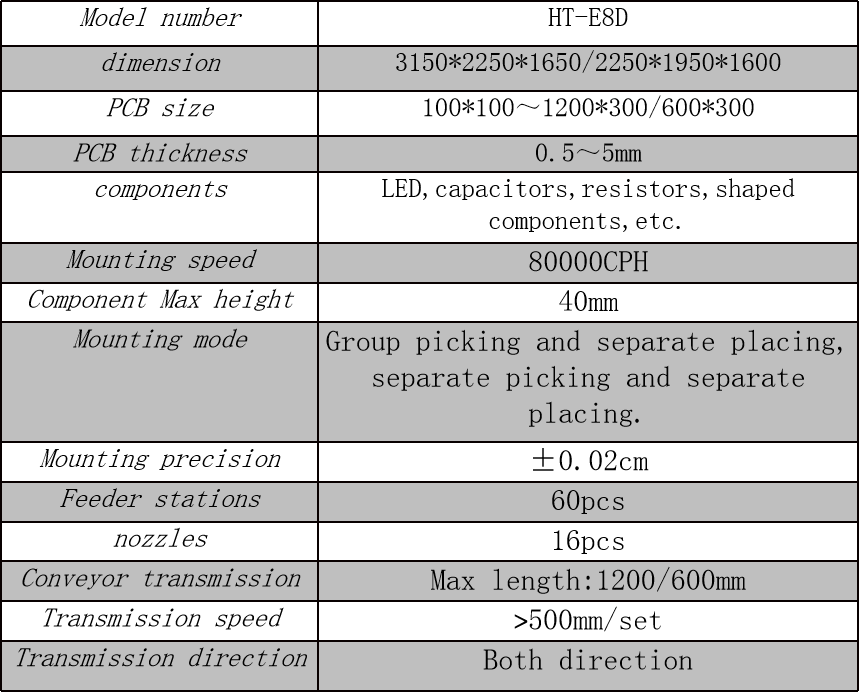

technical parameter

Product Features

- X、Y、Z drive way is high-end magnetic linear motor+servo motor.

- Install 4 camera and adopt vision for the flight identification, mark correction.

- PCB clamping is electric clamping+adjustable pressure pneumatic.

- Vision for the flight identification ,mark correction.

- Electronic feeder feeding system.

- Non-stop material re-loading function.

- Auto-optimization after coordinates generated.

Packing and transportation

We usually use waterproof material to pack our products in wooden cases. If the customer has special packing requirements, we can negotiate and conclude a contract. Partial shipments and transshipment are subject to the contract.

We usually ship within 30 days of receipt of payment.

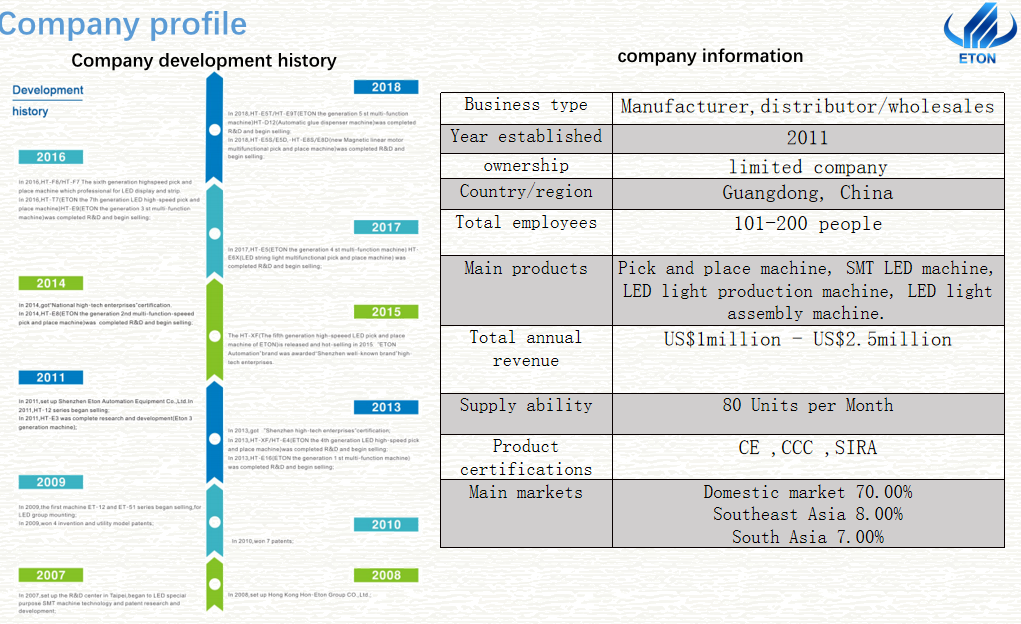

Company profile

In November 2011, Shenzhen ETON automation equipment co., ltd. was established in Shenzhen, China. It is a national high-tech enterprise dedicated to the research and development, production, sales and after-sales technical service of SMT high-speed SMT mounter. Our management policy is sincere operation, concentrate on research and development, manufacturing, intimate service, customers rest assured. Our aim is to create value for customers and benefit for the society. We aspire to be the world's most competitive placement machine and cutting-edge electronic testing equipment manufacturing and service provider.

The company has independently developed a number of intellectual property technologies, including 9 invention patents, 112 practical patents and 12 software Copyrights.Successively obtained "Shenzhen high-tech enterprise", "national high-tech enterprise", “Shenzhen TOP brand”, “2015 LED technology innovation award” ,“industry special contribution award” ,“the 4th China LED first innovation award” ,“industry special contribution award”, “double soft enterprise”and so on.

Business terms:

| Accepted delivery terms |

EXW, FOB, CIF, CFR |

| Accepted payment currency |

USD,CNY |

| Accepted payment type |

L/C, T/T |

| Nearest port |

Shenzhen |

supply ability

80 Unit/Units per Month

FAQ

1) Do you have oversea after sale service?

We have set up an overseas office in India.We can offer technical support abroad. If you have any technical problem, our engineers will support you promptly.

2)How is the training?

You can send your engineers to our workshop to study, or we can send our engineers to your workshop for guidance. We guarantee that the training will not be completed until your operators are fully trained.

3) It’s hard to use the machine?

No, not at all. Touch screen display, English operation interface. Generally training about five days can be skilled in the operation of the machine.

4) Does your machines have quality certificates?

We are high-tech enterprise with CE,SIRA,CCC .

5)How about the warranty?

We guarantee it for one year free of charge. Software updates are free for life.

Knowledge of mounter industry

The difference between high-speed placement machine and multi-function placement machine

l Features of High Speed Placement Machine

1) High-speed placement machine structure can be composed of any structure. Structure: turret type, compound type and large parallel type, etc.

2) The range of mountable components for high-speed mounting machine is usually small, and the range of mountable components is from 0603-7474;

3) The packaging form of the components attached to the high-speed placement machine can usually be only rolled tape;

4) Many high-speed mounting machines can be mounted at full speed when picking up and mounting small components, and the number of high-speed mounting machine heads is more;

5) The patch suction nozzle of a high speed placement machine usually has only a vacuum suction nozzle.

l Features of Multifunctional Placement Machine

1) Multi-function placement machine can mount high-precision large, special-shaped components, generally can also mount small flake components, can cover almost all components range, so called multi-function placement machine.

2) The structure of multi-function placement machine mostly adopts arch frame structure, which has the characteristics of high precision and good flexibility.

3) The multi-function placement machine mostly uses the circuit board fixed type, uses the mount head movement to realize the X and the y localization, will not cause the large or the heavier component to shift because of the inertia because of the table surface movement.

4) Multi-function patch can accept all material packing methods, such as reel, tube, box and tray. In addition, when more disk material, can be added multi-layer special tray feeder.

5) In addition to the traditional vacuum suction nozzle, the multi-function placement machine can use a special suction nozzle for the components which are difficult to absorb by special shape. In addition, pneumatic claw can be used for the components which are absorbed by vacuum suction nozzle.

6) The multi-function placement machine components generally use the upper view camera when correcting, which has the functions of front light, side light, backlight and online light, and can identify different components. If the size of the component is too large to exceed the camera's individual image (FOV), the upper camera can also be analyzed and corrected by multiple post-image synthesis. Some multi-function mounting machine mount head also equipped with mount head moving camera, can identify smaller non-carrying components.

7) Compared with the high-speed mounting machine, some high-speed mounting machines can reach 5~10 times faster than the multi-function machine can mount the same components. Therefore, in medium and large-scale production, generally according to the characteristics of the product will be reasonable configuration, so that the efficiency of each equipment is close to high.

Generally speaking, high-speed placement machine is used to mount resistance, capacitance and small three-tube components, the pursuit of mount speed, mount speed is much faster, multi-function placement machine is used to mount pin density high profile components, such as IC、 special components.The multi-function placement machine can attach the components attached to the high-speed placement machine, but the high-speed placement machine can not attach special-shaped components with high pin density. The main structure of high-speed placement machine is turret type, and the main structure of universal placement machine is arch frame type. Generally large SMT patch processing is to use these two kinds of patch machines together. If the production volume is not large, you can only buy multi-function placement machine for use.

contact

Name:Brynn

Email :Brynn@eton-mounter.com

WeChat:13802252825

Telephone:138 0225 2825